2017 MHA Annual Meeting

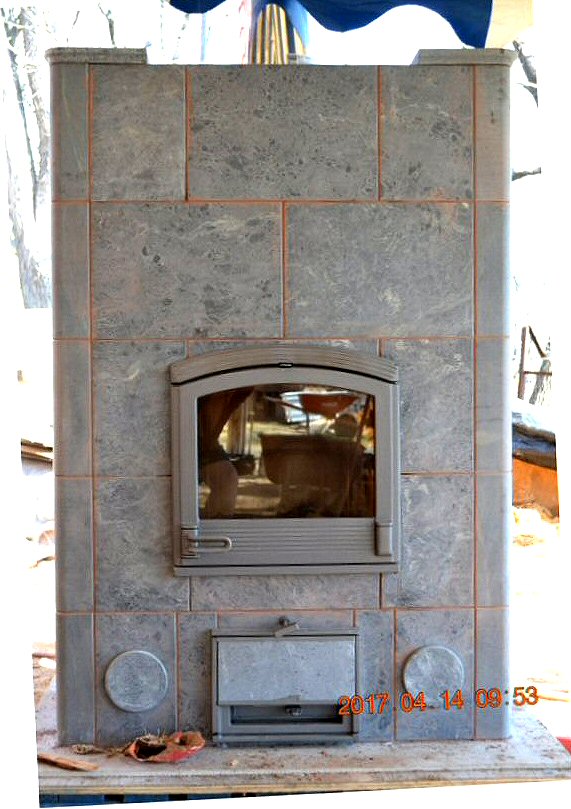

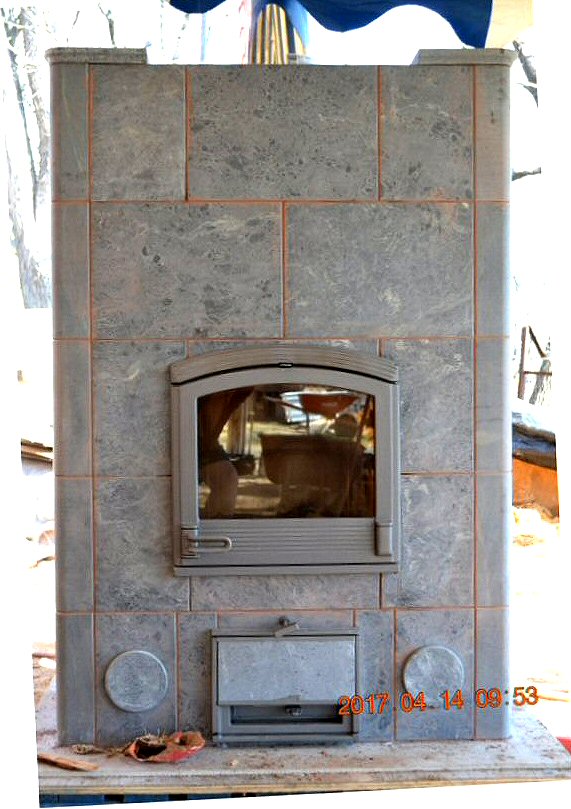

Tulikivi

TU-2200 Top Vent

People

36"

Castable Refractory Oven Experiment

Kachel

Workshop

Large

Double Bell

Squirrel

Tail Oven

Pat Manley

Oven

Test

Heater by AFPMA

Fire Tube

Multifunctional Masonry Heater

Batch

Rocket Cook Stove and Heater

HMED 22"

Contraflow

Small

Finnish Contraflow for Beginner Masons

Quick Grill

by Chris Prior

Tulikivi

TU-2200 Top Vent

Ecostove

Tiileri Brick Heater Kit

Archguard demo

Presentations

U2200

is a popular mid-sized model (about 4000 pounds).

This

particular heater had been assembled and tested for a week in a lab in

Vermont before being

shipped to Wildacres.

Levelling

the base course.

Pinning

the ash door lintel

Drilling

so liner stones can be pinned (to allow for thermal expansion).

Firebox

is capped with two pieces of cast refractory concrete. Brackets hold

the stones together,

especially

at the corners.

Isoglas insulation is used as gasket and in the back of the heater if

installed near a wall

Onni

Ovaskainen (blue shirt, grey cap) is in charge of testing at Tulikivi’s

R&D department in Finland.

Soapstone

firebricks form the throat above the firebox.

The

chimney is supported by a steel bracket.

The

capping stones were not installed because it would have required

cutting a hole in them.

Doug

Hargrave is the owner of Mid-Atlantic Masonry and a Tulikivi

distributor for almost 30 years.

Redart

clay slip was used as mortar. On a permanent installation, it would

have been soapstone dust

mixed

with waterglass (sodium silicate).

Thanks

to precise machining of the stones, joints are only 0.5 millimetre

thick (1/64”).

See

also:

2016 Photo

Report

2015 Photo

Report

2014 Photo

Report

2013 Photo

Report

2012 Photo

Report

2011 Photo

Report

2010 Photo

Report

2009 Photo

Report

2008 Photo

Report

2007 Photo

Report

2006 Photo Report

2004 Photo Report

2003 Photo Report

2002 Photo Report

2001 Photo Report

2000 Photo Report

1999 Photo Report

1998 Photo Report

1997 Photo Report

This

page was last updated on February 5, 2017

This page was created on April 18, 2017

Back

to: