| Gallery | The Mall | Member Directory | MHA News | Bookstore | Library | Links | Lopez Labs |

2001MHA Annual Meeting

May 7 - 13, 2001

at Wildacres Retreat,

Little Switzerland, North Carolina

First stop on the way to Wildacres was an MHA heater building workshop at

Jay Hensley's new house in Kentucky. The workshop instructor was

Jerry Frisch. The project was a custom compact heater with a side bake oven.

Link to workshop page.

After the workshop we headed to North Carolina in a convoy of 6 vehicles. We spent the

night in

Asheville and headed out the next morning on the spectacular Blue Ridge Parkway.

En route, we paid a visit to a nearby client of Jerry's to inspect a Biofire

and a Firecrest, and to watch Jerry do the break-in fires with

the clients.

The Firecrest fireplace, manufactured by Lopez Quarries

(and Masonry Stove Builders in Canada).

The stonework is by a local mason.

Jerry Frisch's wolfshead air supply. With glass doors on the

Firecrest, the combustion air blows from the wolf's mouth,

and it becomes the Frisch-Rosin fireplace.

It is very clean burning and emissions certified in Washington State.

This air supply was developed at Lopez Labs, MHA's

test facility.

John Rousseau helps Jerry install the control

for the chimney top damper.

The break in fire in the Firecrest.

Each Biofire is custom designed and calculated for a specific

house by the Austrian factory. Instead of paper plans, it comes

with a scaled 3-d wooden assembly model. This photo shows

two courses of firebrick modules in place.

The course by course assembly model laid out in order of installation.

The break-in fire in the Biofire. Cleanout plug into the first channel is visible.

We started our business meeting in the Wildacres library the next morning.

It was an auspicious year, as we were able to conduct all of our general

business in one day, leaving the rest of the week for hands-on workshops

and training. This format resulted in the best turn out to date.

One of the items of business was MHA's new sets of heater plans

that will be for sale to the public. Jerry leads the discussion on plans

for a Swedish heater.

Very early the next morning, we took two trucks to Tom Trout's

house to pick up materials for the workshops.

Tom always has new and interesting heater related tid-bits

lying about. This is Sleepy Hollow's drop down chimney top

damper. It has received good reviews from several people

in the know, compared to other types of top dampers.

Erik Nilsen and William Davenport start the base for the 36" X 24" contraflow

heater workshop. Click here to see the full workshop.

The base for the Superior Clay bake oven workshop is started.

Click here to see the workshop.

Dann Carnes.

Pat Manley.

Peter Skove takes notes.

Frank Sotero demonstrates proper trowel technique.

Pat Manley and Bev Marois take a break.

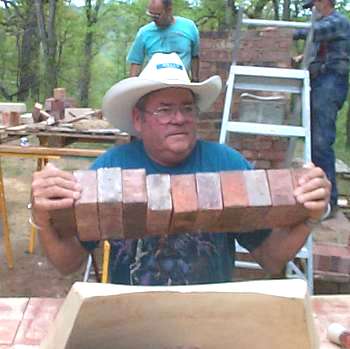

Marcus Flynn demonstrates his brick skills.

Nobody could beat Jerry's 11 rowlock lilft. Not bad for a geezer.

William Davenport takes his hands-on

certification test. There are currently 13 MHA-certified

heater masons, and another 12 in the pipeline.

Mark Klein takes his hands-on test.

Check out Mark's company - they do some

pretty cool stuff.

Patrice Dupont and John Rousseau amaze Gary Hart

during the brick arch demonstration. The side thrust

from Jerry's foot is all that stands between these two

Canadians and the ground.

Watching the sun set over the Smokey Mountains from the patio.

Jerry shows a video of a recent Swedish oven that he built.

Ken Matesz takes his hands on test.

Peter Skove takes his test.

John Rousseau

Ken Caldwell

Jean Pivard (right) joined us from France to do a workshop on the

Le Panyol oven that he manufactures. It is manufactured from a unique clay in Provence

that is found nowhere else. Products have been made from this clay

since Roman times. click here to see the workshop

The fired clay is somewhat porous, and has a good balance of

heat retention and porosity. Professional pizza bakers are reporting

large fuel savings in comparison to their previous ovens.

Getting ready to set the keystone.

Pat Manley gave a very moving presentation on his

Masons on a Mission project. Please consider

supporting this

project, which provides indigenous Mayans in the western

highlands of Guatemala with smoke-free cookstoves and has

tremendous benefits on the health of native women and children.

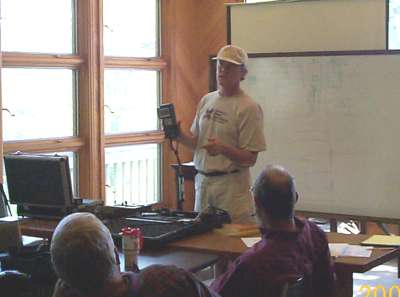

I gave a seminar on basic combustion principles and heater testing.

Shown here is Lopez Labs' portable combustion analyzer.

We continued last year's effort to develop a database for safety

testing of masonry heaters. This year we burned the 36" x 24"

contraflow constructed at the workshop with 5 back-to-back

loads of wood. Pat Manley is shown here documenting the second

fuel load, approximately 28 pounds of dry hardwood.

The first load stacked and ready for light off. The heater was cured

the previous day.

Testing in progress.

The test lasted 9 hours. Mark Klein is on the left taking the final

surface temperature readings while Jerry records them. We stopped

the test after all of the test spots had peaked. We also did a heat

transfer comparison between a 1/4" mineral wool expansion joint

and a cardboard expansion joint. To see a write up of the whole test

check the Lopez Labs site in a few days.

Rod Zander decides to do an impromtu spalling test with a garden

hose. That's steam coming off the heater, not smoke.

The surface temperature of the heater was over 300F after 5 loads of fuel

(about 100 - 150 lbs).

The highlight of our meeting was the Panyol oven test.

The only way to test it properly was to make some pizzas.

Tom Trout was the pizza chef.

Jean Pivard loads a pizza.

The first one looks good. This one has garlic, olive oil, salt and pepper.

No cheese, because the oven is too hot yet. It took about 3 minutes

to bake.

The lapidary group was sharing Wildacres with us. We decided

to invite them down for a pizza party. They are suitably

impressed with the final product.

We cooked 40 pizzas. Everyone was impressed with the oven's performance.

Four hours later the oven temperature was still 600 F.

Dismantling the oven. Shown is the insulation over a layer of paper and clay. In a

permanent oven

the pieces would be mortared together.

David Moore takes the oven home for the kitchen in his new house.

Mark Klein wrote his certification exam during his visit to Wildacres.

He had already fulfilled all of the other requirements, and

Bev presents

him with his shiny new MHA Certified Heater Mason certificate, number 013

See also,

2000 Photo Report

1999 Photo Report

1998 Photo Report

1997 Photo Report

This page was last updated on May 7, 2002

This page was created on May 12, 2001