2017 MHA Annual Meeting

Test

Heater by AFPMA

People

36"

Castable Refractory Oven Experiment

Kachel

Workshop

Large

Double Bell

Squirrel

Tail Oven

Pat Manley

Oven

Test

Heater by AFPMA

Firetube

Multifunctional Masonry Heater

Batch

Rocket Cookstove and Heater

HMED 22"

Contraflow

Small

Finnish Contraflow for Beginner Masons

Quick Grill

by Chris Prior

Tulikivi

TU-2200 Top Vent

Ecostove

Tiileri Brick Heater Kit

Archguard demo

Presentations

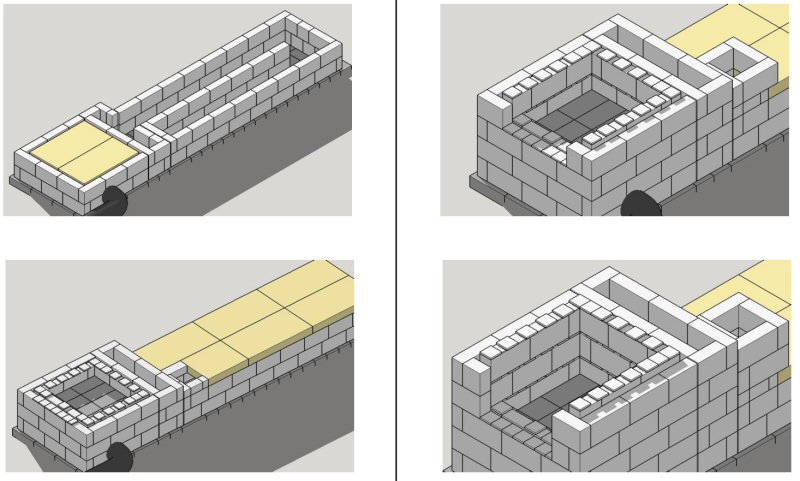

Download

assembly drawings

Download

Sketchup model

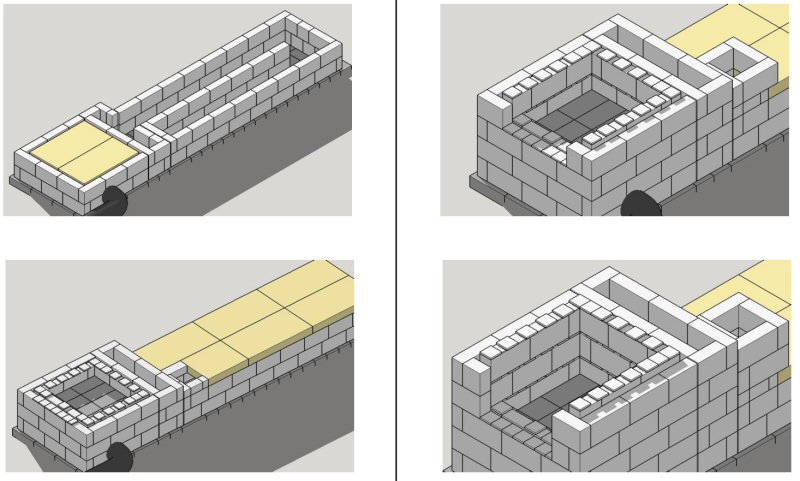

Base

and firebox floor.

Firebox.

The

gap between the firebox and the outer skin is a passageway for

combustion air,

which

enters the firebox through horizontal slots at each course.

Horizontal

air slots are visible. The are created by sitting the firebricks on

spacer shims.

Firebox

lintel brick.

Strips

of white ceramic fiber create expansion joints between the firebox and

the heat exchanger.

The

gases will exit the firebox at the top and then downdraft through the

first heat exchange channel.

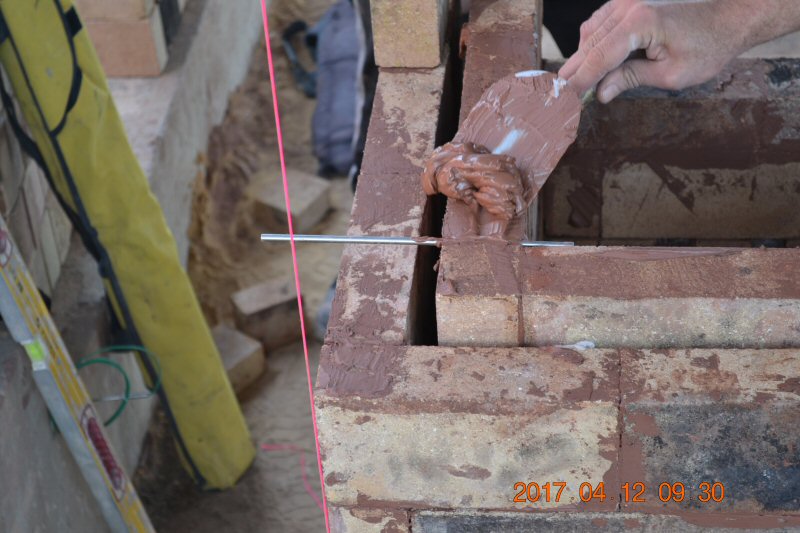

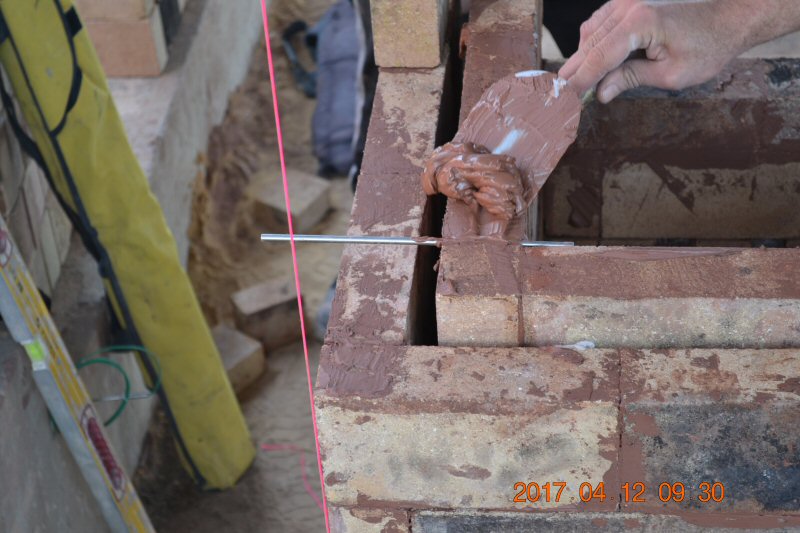

A

stainless tube is embedded that will act as a pressure measuring

location for the top of the firebox.

Firebox

ceiling is a piece of vermiculite board

Exit

from the downdrafting heat exchange channel is visible at the bottom.

The vertical brick is a temporary support.

View

of the air slots.

After

the gases leave the downdrafting heat exchange channel, they enter the

left side of the horizontal bench.

They

return at the end, and will exit the right side at the top of the bench.

The

gases enter a vertical section of brick chimney. The transition

section, shown above, will support 8" stainless pipe.

Firebrick

chimney section.

Capping

slabs over firebox.

Ready

for stainless pipe.

Capping

the bench with soapstone slabs.

Soapstone

slabs are installed as bench tops.

Installing

the firebox door.

Damien

Lehmann designed the heater. He is a founding member of AFPMA, the

Masonry Heater

Association

of France. He has developed an open source version of a handbuilt

heater calculation model, based on EN-13384.

AFPMA

is collaborating with MHA to build a testing lab in France and in Canada to do

verification testing to proof the calculator model.

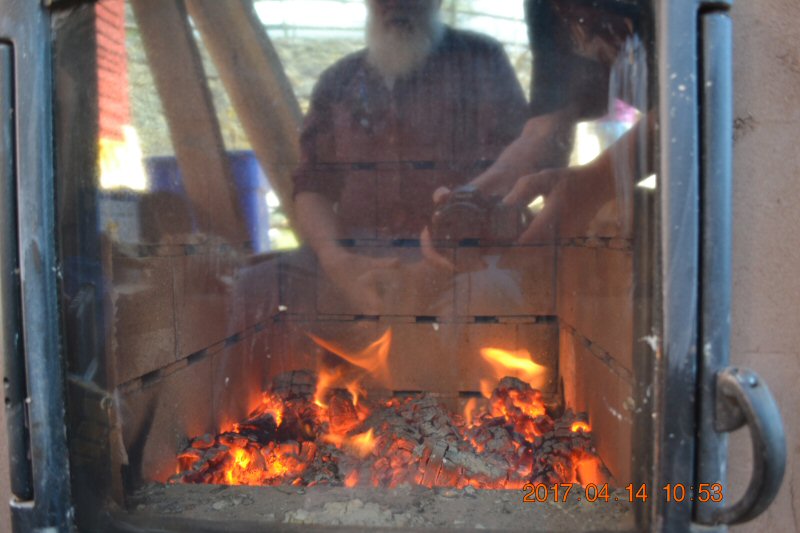

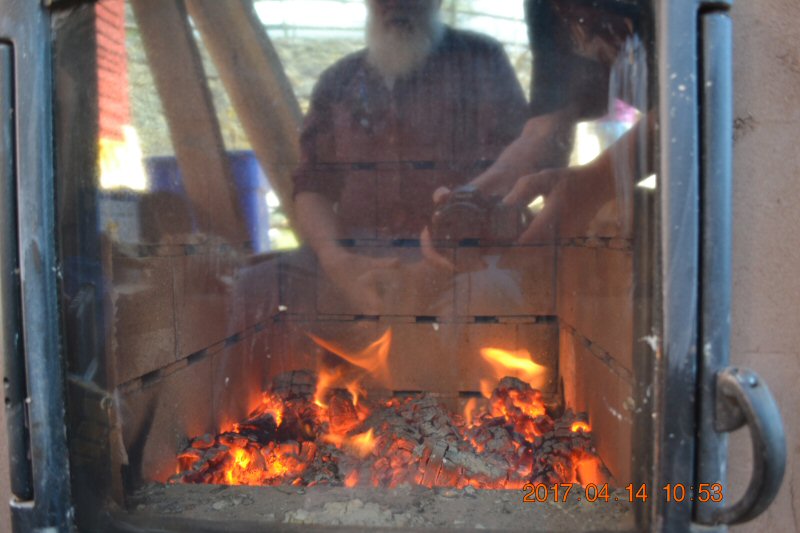

Curing

fire with small wood.

Carsten

Homsted sets up the

Condar portable dilution tunnel particulate sampler.

Curing

fire continues with a load of regular firewood. The goal is to have the

heater completely dried out for testing the next day.

Next

day mid-day.

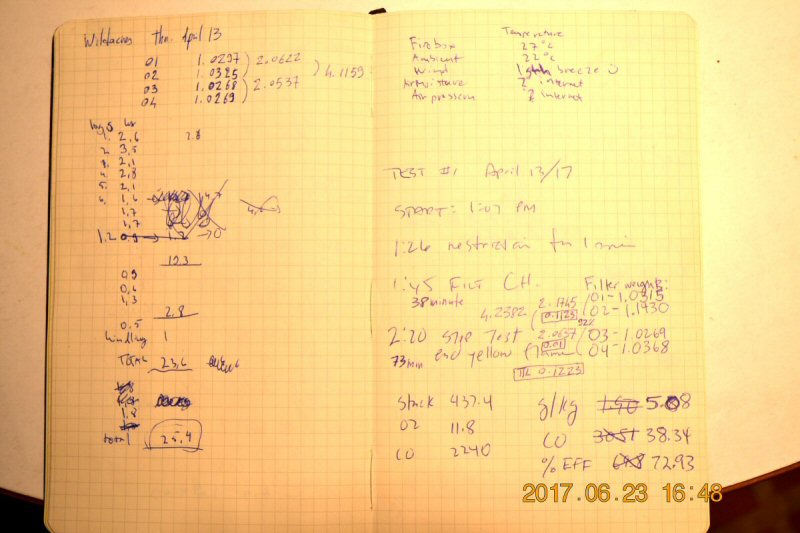

First

test load was lit at 1:07 PM. Note that the camera shows one

hour

earlier. This photo is at 1:40, ie 33 minutes into the test.

The heater has clay plaster, and you can see it starting to dry out

around the door.

Very

intense fire with the Eco-labelled air

system.

Austrian

air specification.

The heater was burning way too fast, and the Condar filter plugged up

at 38 minutes, highly unusual.

PM was 5.08 g/kg, or very high (for a masonry heater).

Spoiler alert: we increased the size of the wood slightly for the next

test, and the PM cam down to 0.7 g/kg.

Burning

clean.

Note the

progression in the drying of the plaster from 54 minutes earlier

Note the

progression in the drying of the plaster from 54 minutes earlier

Carsten

Homsted pulls the final set of Condar filters for weighing.

Laboratory

balance for weighing the 4" glass Condar filters. Set on a solid

non-vibrating surface.

Balance

resolves to 0.0001 gram

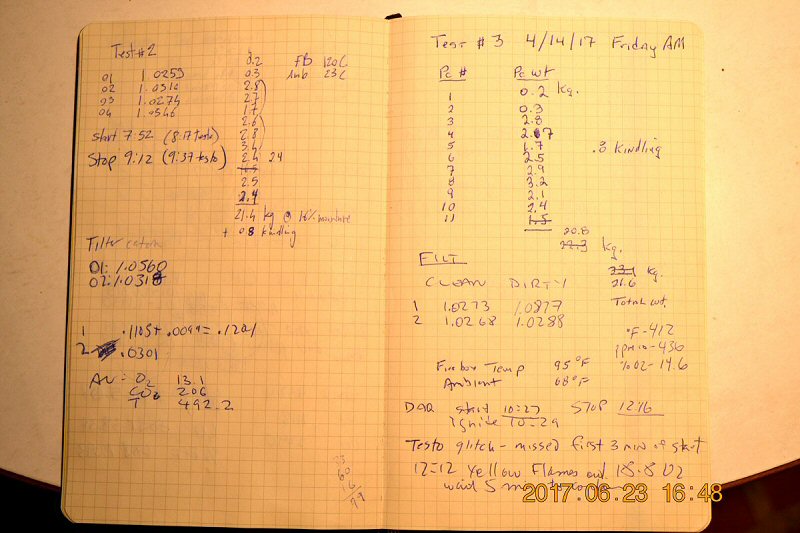

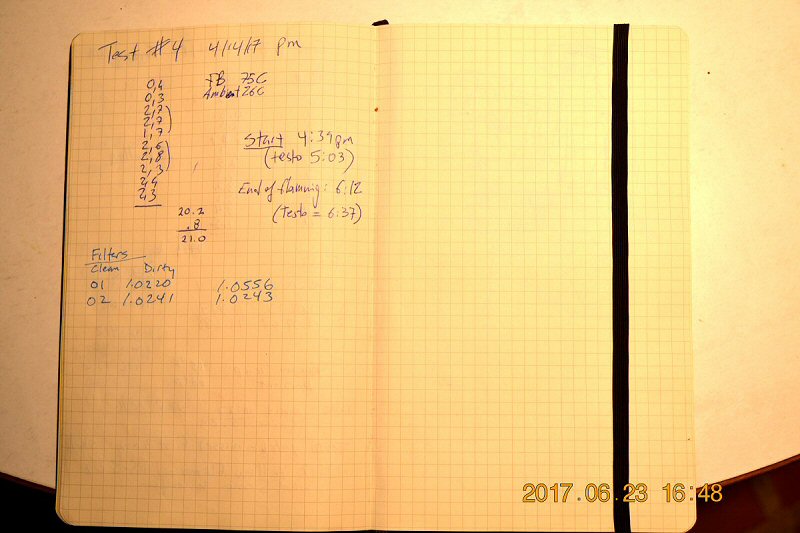

Test

#2, the following day.

Ben

Myren weighing kindling for fuel load.

Ben

runs an EPA accredited testing lab in Colville, WA and has more than 30

years experience in the field

For

the first test, the firebox was still fairly hot from curing late

the day before, which also contributed to the over-amping. It was a

valuable demo. Comparing predicted values from the calculator,

indicated that the heater needed more heat exchange. Ie.., stack

temperature was too high..

This resulted in the burn rate going high enough that there was not

sufficient air anymore, resulting in high emissions.

Alexandre

Paquin helps Ben Myren with the wood.

The

weight is written on each piece, and the geometry of the fuel pile is

documented.

The

computer on the right runs the Testo 330-2 gas analyzer.

The

other computer is from the MHA

lab

in Shawville Quebec

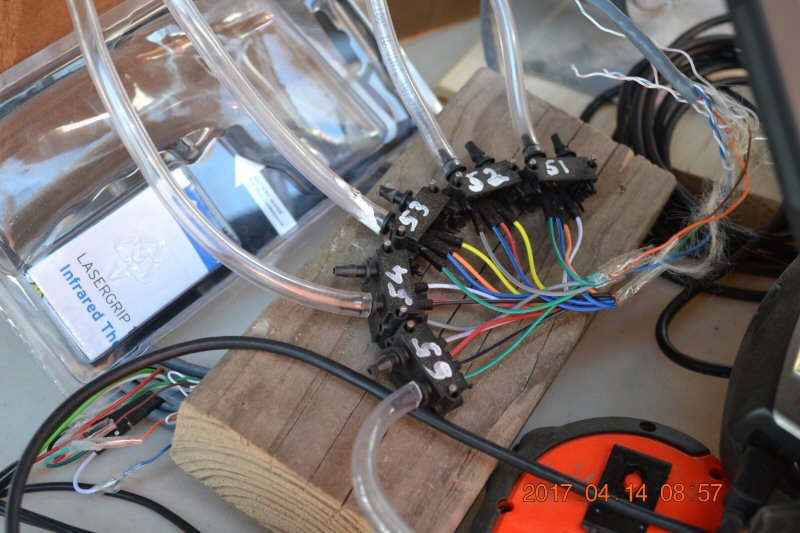

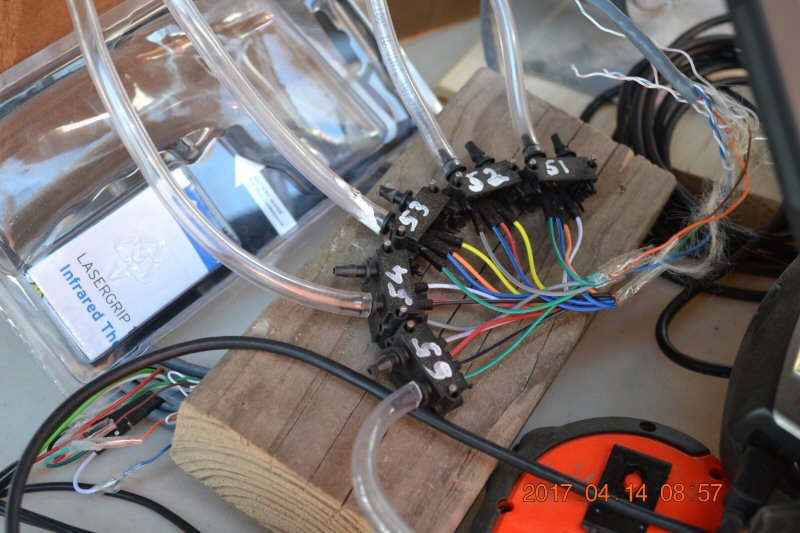

A scaled

down 5 channel version of the pressure sensing setups that we have at

the MHA

and AFPMA labs.

The

Sensirion

SDP-610 digital sensors are very accurate and repeatable with

a resolution of 0.1 pa.

They

are part of our collaborative project

to verify a software model for one-off handbuilt heaters.

MHA

lab computer. The white dongle at the back is an IOWarrior

It provides the digital interface between the sensors and the

computer's USB port.

Note there are only 4 wires, yet up to 128 separate channels of

pressure readings can be connected via the

I2C digital communications protocol. The data logging is done via DAQFactory Pro.

Stacking

the load for the second test run. Larger fuel pieces were used,

compared to run #1.

Fuel

load was 21.9 kg at 16% moisture.

Weight

and piece number (position in the firebox stack) is marked on each

piece and recorded.

First

row.

Second

row.

Third

row.

Kindling

sits in a gap between the two larger pieces.

At

10 minutes, only white steam is visible from the stack.

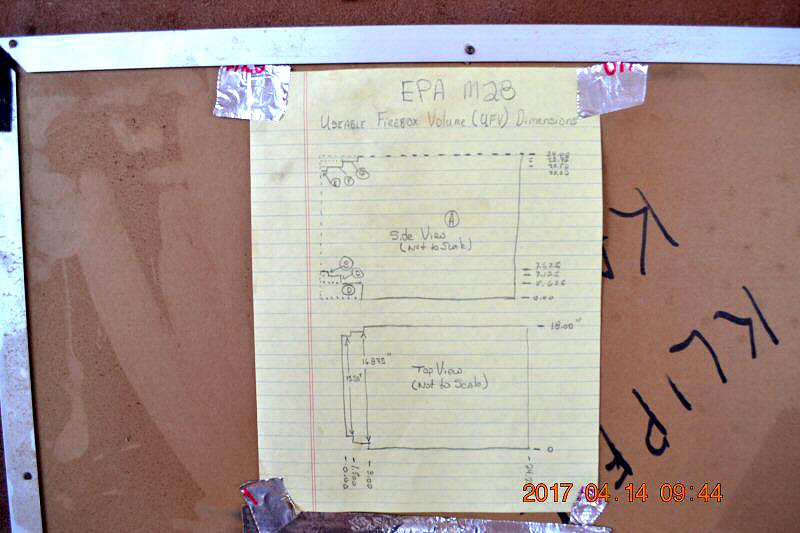

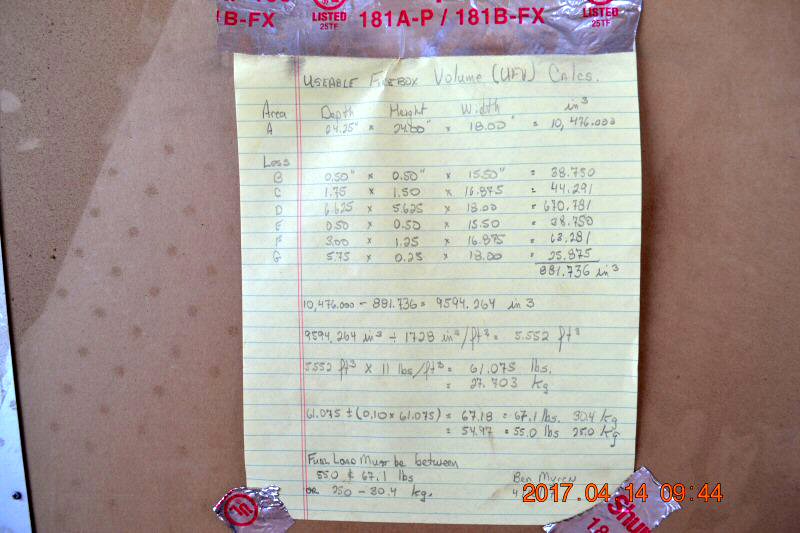

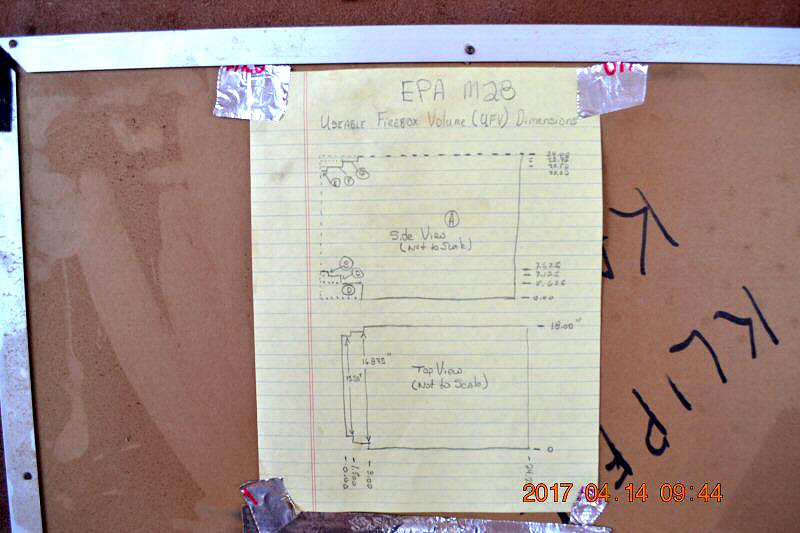

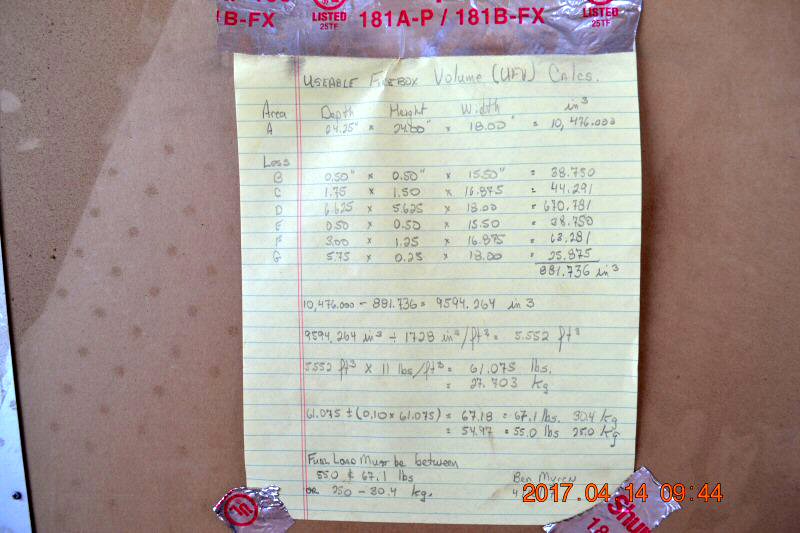

Ben

Myren made a drawing explaining how fire box volume is calculated for

EPA certification testing, to determine the fuel load.

Fuel

load was 21.9 kg plus 0.8 kg kindling for a total of 22.7 kg.

According

the new ASTM cordwood method that will be used for EPA testing for

woodstoves, the load for a firebox this size should be 25.0 - 30.4 kg.

Labjack T7 Pro

It

can handle up to 40 channels of thermocouples or other sensors, and is

interfaced with DAQFactory Pro at the MHA and AFPMA labs.

At

13 minutes, the stack temperature is high enough that there is no steam

condensing.

PM

for this run was 0.7 g/kg, which is cleaner than the average of 6

common pellet stoves that we have measured with the Condar.

View

of portable testing setup showning pressure and temperature connections.

Firewood

pieces with individual weights marked (in lbs).

Stacking

fuel load for third test run, Friday afternoon (pizza party day).

Test

nearing the end, as the pizza party is gearing up in the background.

One

of many reloads.

We

had the chance to do a bit of destructive testing ;-) to see how the

single thickness firebox would stand up.

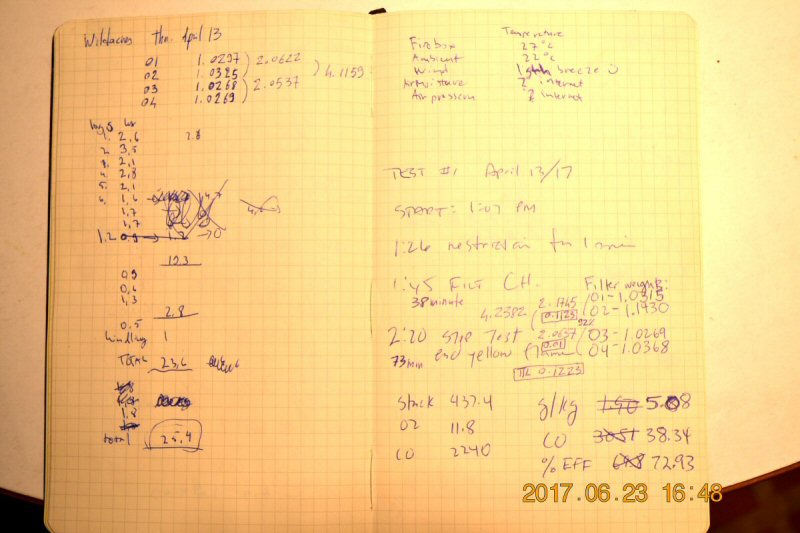

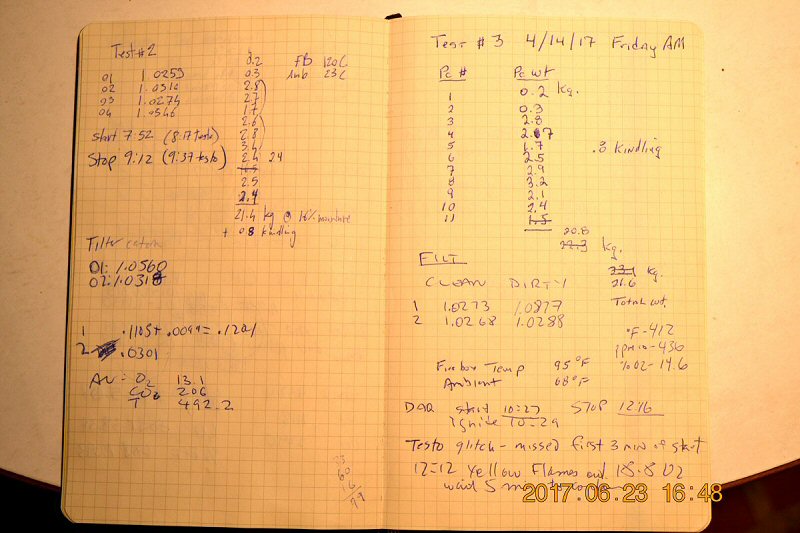

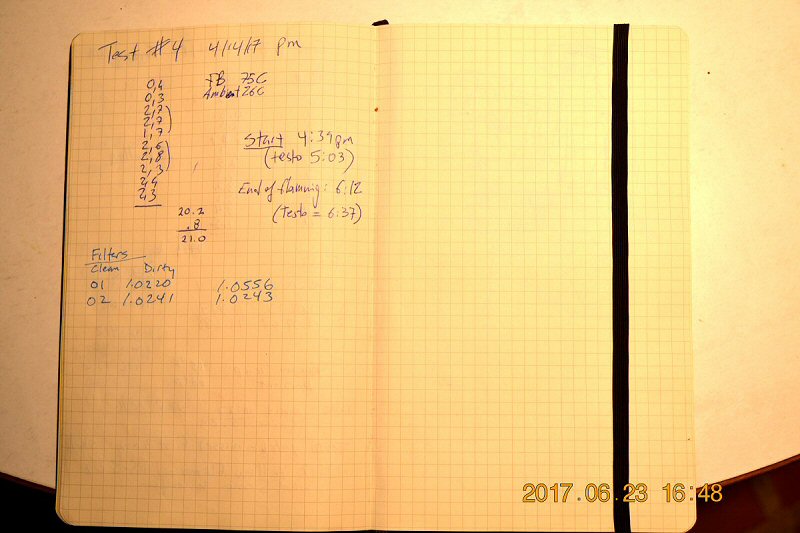

Lab

Notes:

See

also:

2016 Photo

Report

2015 Photo

Report

2014 Photo

Report

2013 Photo

Report

2012 Photo

Report

2011 Photo

Report

2010 Photo

Report

2009 Photo

Report

2008 Photo

Report

2007 Photo

Report

2006 Photo Report

2004 Photo Report

2003 Photo Report

2002 Photo Report

2001 Photo Report

2000 Photo Report

1999 Photo Report

1998 Photo Report

1997 Photo Report

This

page was last updated on February 2, 2018

This page was created on April 18, 2017

Back

to:

Note the

progression in the drying of the plaster from 54 minutes earlier

Note the

progression in the drying of the plaster from 54 minutes earlier