| Gallery | The Mall | Member Directory | MHA News | Library | Links |

"This stove belongs to all the people in the world living in sparsely wooded areas, living with the three stone fire that causes lung and breath diseases."

------------------------------------------------------------------------

To: Norbert Senf <mheat(at)heatkit.com>

From: Richard Jussel <shorty.feuermacher(at)telering.at>

Subject: Re: Thank you

Date: Sun, 27 Apr 2008

Norbert:

The idea for this stove came in 1999, and a team from The Austrian Tile Stove Association helped to make this stove close to perfection.

I have been using the name "The Energy Saving Stove", which is designed for heating and cooking.

This stove belongs to all the people in the world living in sparsely

wooded areas, living with the three stone fire that causes lung and

breath diseases.

It should help to make a cleaner kitchen environment and to save fire wood.

The stove has an overall efficiency of 84 % (European method) for cooking and heating.

It keeps water bowls warm for more than 6 hrs when the fire has stopped.

The energy saving stove is built only with unburned clay bricks and a

few part of scrap iron to strenghten the cover that carries the load

of the big water bowls.

This ensures that it is nearly 100 % appropriate technology.

So, I am pleased if you publish this idea that could be replicated all

over in the world where our Mother Earth and her inhabitants need

protection.

With best regards

Richard

-------------------------------------------------------------------------

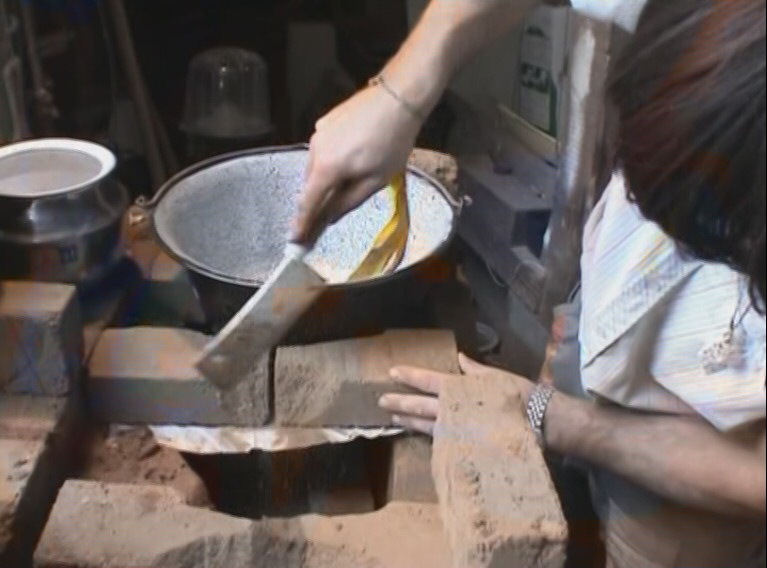

Raw material for bricks. A local fatty clay and sharp sand.

Finished mix ready to be tamped into mold.

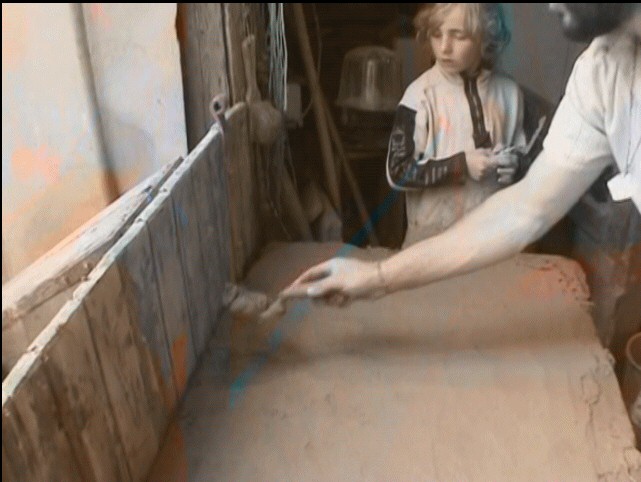

Using a simple foot operated mold. Foot pressure on the board releases the brick.

The bricks air dry for 3 weeks.

The bricks are dipped on the edges that will be mudded.

Building the base.

Making a very flat clay surface for layout work.

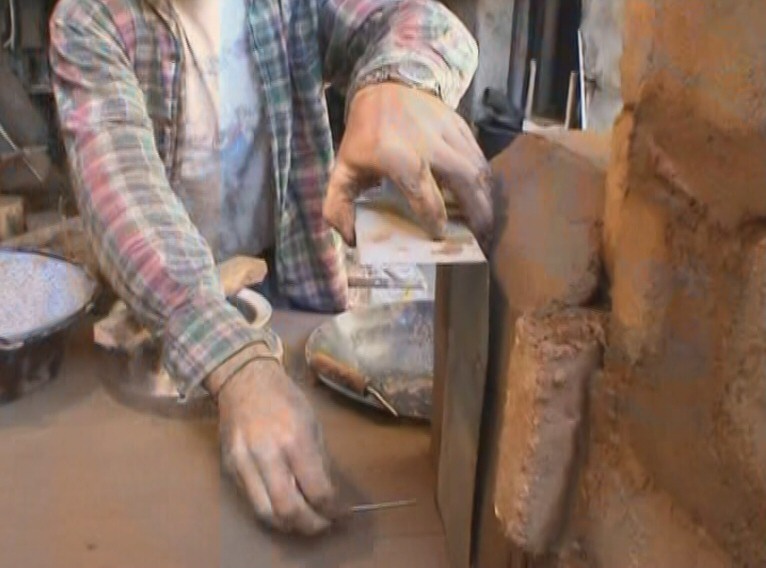

Chopping bricks to length with a cleaver. The bricks are surprisingly hard - a good mix.

Inside corner is rounded for smooth gas flow.

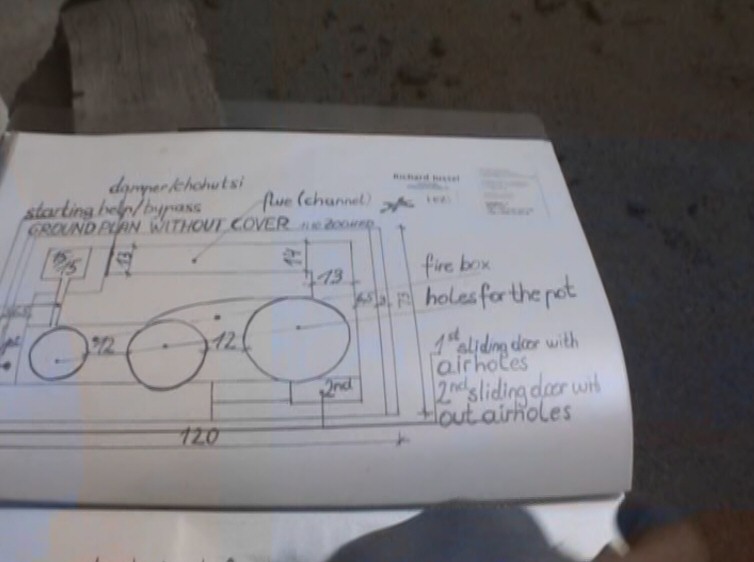

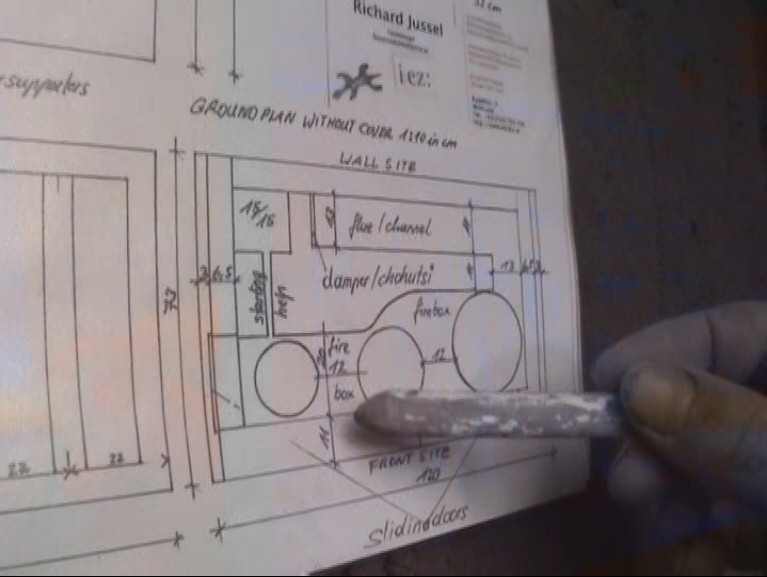

Firebox layout.

Fitting one of the three pots. This is the only metal on the stove, except for the damper plate and a bit

of reinforcing here and there using scrap metal.

Creating a gas slot.

Smoothing out the exit run.

Rounded corner at exit to chimney, to minimize friction.

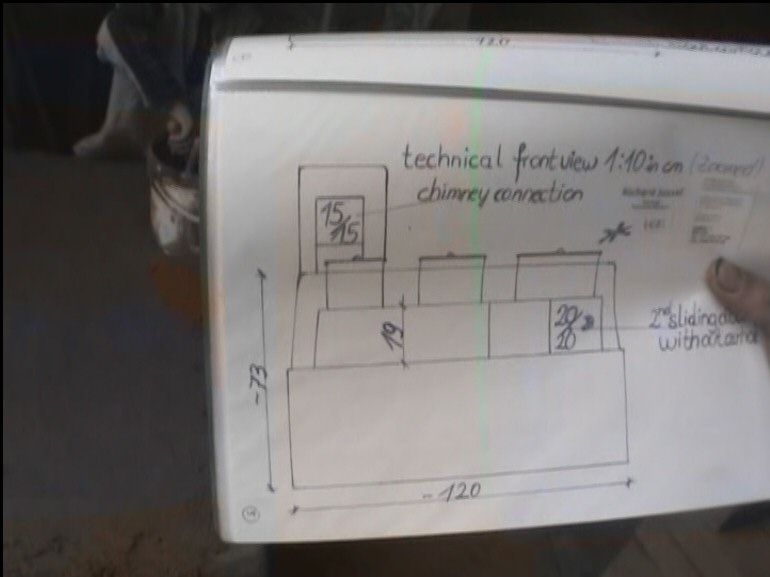

Laying out the exit box for the chimney connection.

This is where the stove exits into the chimney.

scraping out a groove for the sliding damper plate, using the trowel edge.

Fitting the damper.

Laying out the covering for the top, which will need to hold 3 pots.

Fitting bricks around the sliding clay firebox doorl.

Preparing to fit the pot to the bricks by wetting the bricks. This softens them so they can be shaped.

Using the cleaver to shape the bricks.

Fitting the wok.

![]()

Reinforcing using scrap metal

Building the exgterior chimney. Stove connection is visible at back

Scraping through a hole for the rear channel cleanout.

Wetting the stove to get it ready for plaster.

Truing up the inside.

Punching a hole in the sliding damper to hold a nail as a stop in the open position.

Chimney clean out plug

Plug is mortared in place. When mortar is dry, trowel is used to scrape plug free, making for a tight fitting plug.

Bake oven sliding door.

Lighting the curing fire.

Sliding firebox door with air holes

Cured stove.

Making a plug for the wok hole, when the wok is being used to serve food at the table.

First the wok is used to form a clay mold for the plug.

A wire lifting handle is fabricated.

Clay mold is lined with plastic.

Plug is cast from clay (adobe) mix with handle inserted.

Cooking the first meal.

Checking the bake oven. Raking out a bed of coals.

Inserting cake pan with cake.

Finished cake.

Retrofit improvements: weak areas are reinforced with sisal fiber and clay.

Wetting the repair area in preparation for patching.

Strips of sisal rope are embedded in the clay patch.

A piece of burlap is embedded in clay to reinforce the rear deck area.

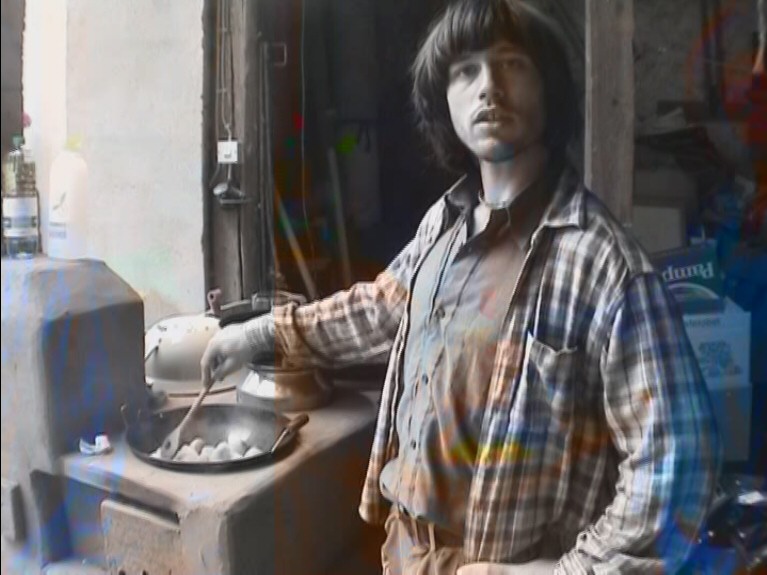

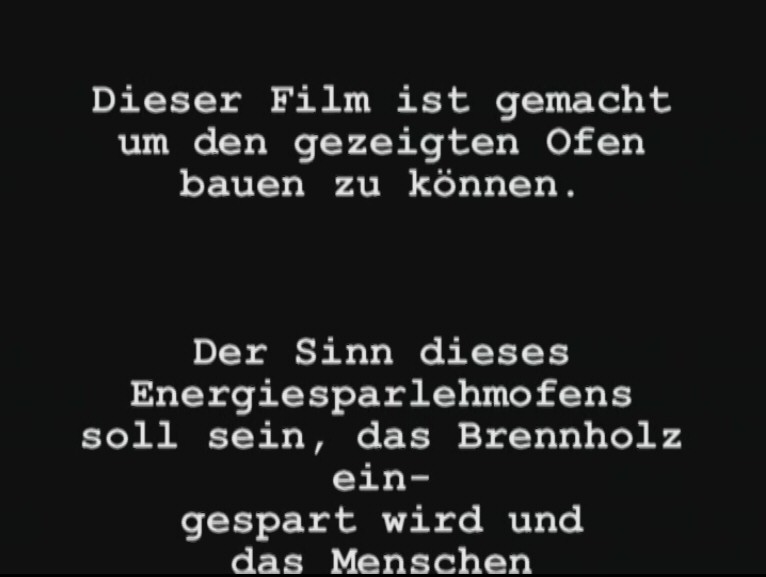

This film was made so that people can learn to build the stove from watching it.

The purpose of this Energy Efficiency Clay Stove is to save fuel, and so that poor people around the world can live in

a little more comfort (no smoke in the kitchen, being able to cook while standing or sitting).

The stove is built almost entirely of clay, and is therefore affordable for everyone.

This wood fired cookstove was conceived and developed by Richard Jussel, master stove mason www.feuermacher.com

in co-operation with:

Working on this video project were:

Cameraman: ---- Michael Kramer

Helper: ---------- Enrico Landwehr

Brickmaker: ------Regina Schleyer

Chief mason: -----Martin Schleyer

You can order a copy of this video (5 Euros for the 30 minute short version, 10 Euros for the 3 hour long version)

from Martin

See also,

2007 Photo Report

2006 Photo Report

2004 Photo Report

2003 Photo Report

2002 Photo Report

2001 Photo Report

2000 Photo Report

1999 Photo Report

1998 Photo Report

1997 Photo Report

This page was last updated on

April 4, 2020

This page was created on April 21, 2008