2015 MHA Annual Meeting

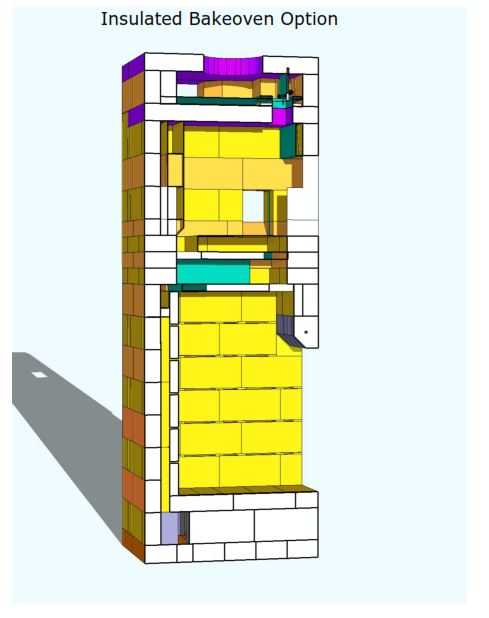

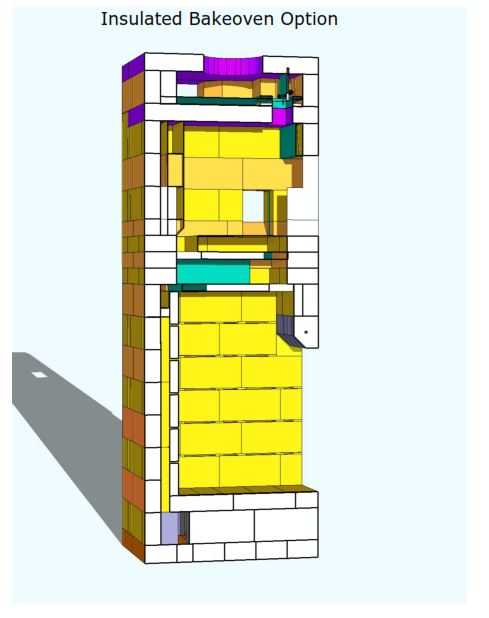

Norcore 5 run with Eco Firebox and insulated black oven

with Norbert Senf and Brian Klipfel

Back to Wildacres 2015 Photo Report

Download the assembly PDF

Download the Sketchup model

Wednesday morning, 9:00 am.

Brian Klipfel leads the build.

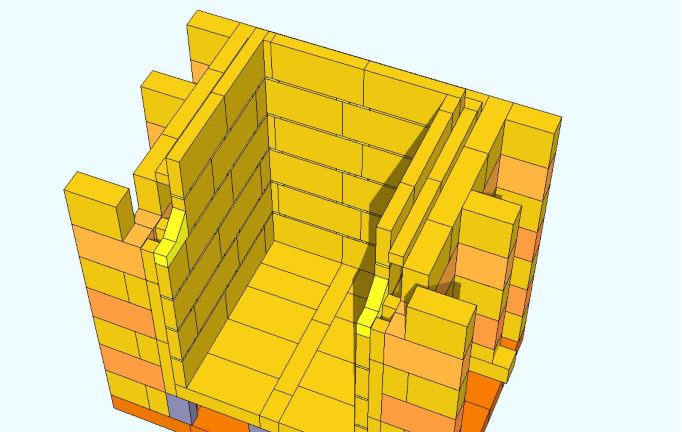

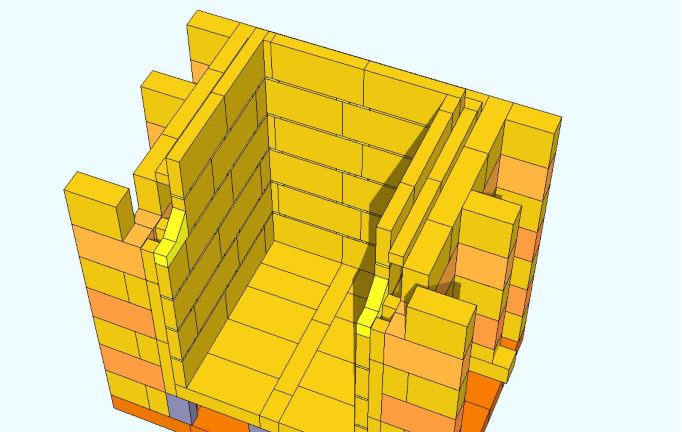

As an experiment, the right downdraft channel is widened by 2.25" and the updraft channel reduced by the same amount.

In

last year's testing, it seemed that the 5 run configuration transfers

less heat than the equivalent downdraft (contraflow) configuration.

Check out the testing page for results.

Bottom end, underneath the firebox floor. Air enters here, and supports are started for the spacers that create the air

distribution channels for the Austrian eco-labelled firebox.

Check out the Eco-firebox specifications.

Laying in the firebox floor.

Alex Chernov brought down some Ortner Haftmoertel. It is a quick set, and gave us extra confidence in gluing the

spacers to the outer firebox.

Washing down the outer firebox prior to gluing on the spacers.

Spacer strips are designed to fall at the firebox liner head joints.

Firebox is lined with firebrick splits (1.25" thick).

This is not ready for "prime time" and simply designed to function for a couple of test runs.

A

real world firebox liner would be at least 2.25" thick. In this case,

we wanted to reuse the existing 18" firebox design without

narrowing the firebox, or redesigning the Norcore.

Starting the firebrick split firebox liner.

Refer to assembly instructions, above, for an enhanced graphical description of the firebox sequence.

Soapstone bake oven floor slab. The slab is insulated underneath with Skamolex high density vermiculite board.

Refer to section drawing, above. There is a second piece of Skamolex visible, that forms the firebox ceiling.

Skamolex is used to form an insulated firebrick chamber for the black bake oven.

The idea is to extend the heat retention ability of the oven.

Outlet from the oven to the downdraft channels is at oven floor level.

With an insulated oven, this will minimize any convection losses into the channel.

This photo was taken at 4:30 pm Wednesday night.

7:30 am Thursday.

Jeff Owens and crew were obviously busy last night, and got the heater face while somebody blinked.

10:20 am. Facing is done.

10:30 am. Carsten Homstead starts mounting the doors.

The bricks are still sopping wet, so no drilling into masonry can happen yet. The doors are mounted temporarily with wire,

so that we can get the curing fire started and dry out the heater.

Draft is poor as one would expect.

The heater is designed for a bypass, but no bypass damper is installed.

A torch directly onto the chimney pipe helps to get the draft going.

11:00 am. Curing fire is lit.

Jessica applies a cast clay fleur-de-lis decoration that she made in her studio.

Start was relatively clean, considering the wet heater and so-so firewood.

A bit of smoke mixed with a lot of steam is coming from the chimney.

The bricks were fully wet, and it is amazing that Jeff was able to do such a good job laying them.

Note the compression squeeze-out on the lower mortar joints.

Scott Goodman was in charge of amping up the curing fire. Coincidentally, Scott is a fireman in Rochester.

3:12 pm. Four hours of solid firing, and the bricks are starting to dry out arount the top of the door.

This is one of the hottest and most highly stressed areas of a masonry heater.

Check out the heater testing section, to see the timeline of the curing sequence.

Continue to :

Heater testing and teardown

See also:2014 Photo Report

2013 Photo Report

2012 Photo Report

2011 Photo Report

2010 Photo Report

2009 Photo Report

2008 Photo Report

2007 Photo Report

2006 Photo Report

2004 Photo Report

2003 Photo Report

2002 Photo Report

2001 Photo Report

2000 Photo Report

1999 Photo Report

1998 Photo Report

1997 Photo Report

This page was last updated on April 24, 2015

This page was created on April 23, 2015

Back to: