| Gallery | The Mall | Member Directory | MHA News | Bookstore | Library | Links |

Small Contraflow Heater Workshop

May 9 - 12, 2001

at Wildacres Retreat,

Little Switzerland, N.C.

Note: Jerry Frisch's heater plans for this

workshop

can be downloaded at the MHA Members' Lounge

A burn test was conducted on this heater. The results are available here

Also see: Photo Sequence by Carl Oehme (2008)

Heater base. Outside finished dimensions are 36" x 24"

The downdraft channels are lined with clay flue liners.

Cross section of downdraft heat exchange channels is 4" x 13.5".

Liners were cut from standard 12" x 16" flue liners.

Fiberglass rope is siliconed to the liners as to provide the primary

expansion joints for the heater.

Heater base run. Downdraft channels exit to rear into an 8" round

stove pipe. Triangular piece in front is to support firebox floor.

Clay bricks are laid up in clay/sand (adobe) mortar.

Firebox floor consists of two firebrick slabs. Note 1.5" combustion

air slot notched into front of slabs.

Firebox floor in place. Note rear expansion joint created by

1/4" mineral wool blanket.

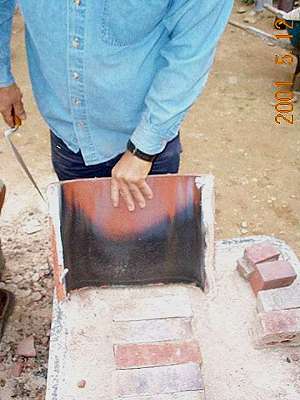

Second set of heat exchange channels in place. Temporary sheet metal in

rear keeps expansion joint material in place. Right side and right rear side were

done in mineral wool, and left side and left rear side were done in cardboard

for heat transfer comparison purposes. Note cardboard being adjusted on left

side.

View from above. Note void at corners between mineral wool and

brick facing. Some masons slush this solid with mortar to improve heat

transfer and gas tightness.

Firebox is built. Rear firebox section consists of a

2.25" firbrick on edge plus a 1.25" firebrick on edge

to meet building code requirement for 8" overall

wall thickness. Different expansion joint materials

visible left and right.

Firebox at throat level.

Firebox throat detail.

Throat viewed from inside.

Firebox ceiling slabs being installed.

Ceiling slabs are capped with mineral wool and bricks.

A layer of sand is added.

And a final mortar cap. Often, cement mortar is used

for this final cap and a piece of mesh is embedded in it.

A curing fire was lit in the heater. Once the heater was

completely dry, safety testing commenced. Five full

loads of oak with 13% moisture content were fired back

to back. Surface temperatures on the heater exceeded 300 deg. F.

See the test results

The next day, the heater was dismantled. To most people's surprise, only the

top clay flue liners had minor cracking at one top corner.

View from inside. The flue liners are burned completely clean at

the top of the heater.

The mineral wool insulation is intact.

Rear of heater. Cardboard char on the left side, intact mineral wool

on the right. Testing indicated that the mineral wool side ran cooler

than the cardboard side.

Dismantling the channels. The silicone had vaporized, indicating

that temperatures throughout the flue liner exceeded 700 deg F.

Jerry brought along an old door that was used at Lopez Labs for most

of the original heater testing 8 years ago. It was an early prototype

casting for the Heat-Kit door. We called it the "Urban Decay" model.

Lower heat exchangers are completely intact with no

indications of stress.

Air void visible at corners. With mortar slushing, surfact temperatures

would have been even higher.

Middle channel. Original liner was cracked and siliconed back together

prior to installation. White streaks are residue from vaporized silicone.

Lower liner. Silicone is intact. Note slight soot deposit

that would have been present in all liners but burned off.

Edge of soot trace shows temperature distribution along

liner, i.e., slightly hotter at the center.

Base run. Slight blackening, but no deposits. Small amount of fly

ash at right.

Dismantling the firebox. Two types of clay mortart

were used for the firebox construction: Redart and

Superior Clay fireclay. The Superior Clay fireclay

had a better bond.

View of base run from rear.

Also see: Photo Sequence by Carl Oehme (2008)

See also,

2001 Photo Report

2000 Photo Report

1999 Photo Report

1998 Photo Report

1997 Photo Report

This page last updated on June 1, 2008

This page created on May 11, 2001