| Gallery | The Mall | Member Directory | MHA News | Library | Links |

Pat

started the workshop with an introduction to wood fired ovens, and a

description of the materials and techniques that would be

used. Here he is showing a tapered arch brick.

Firebrick hearth layout, arch forms, mineral wool insulation, soapstone sample.

The

oven floor bricks sit on a mortar bed, which sits on a 4" sand bed in

this case. Normally the bricks would sit on a cast slab

sitting on insulation such as Foamglas/

Hearth bricks, with separate perimeter bricks for the oven walls.

Oven floor is 36" wide, which is 4 firebricks.

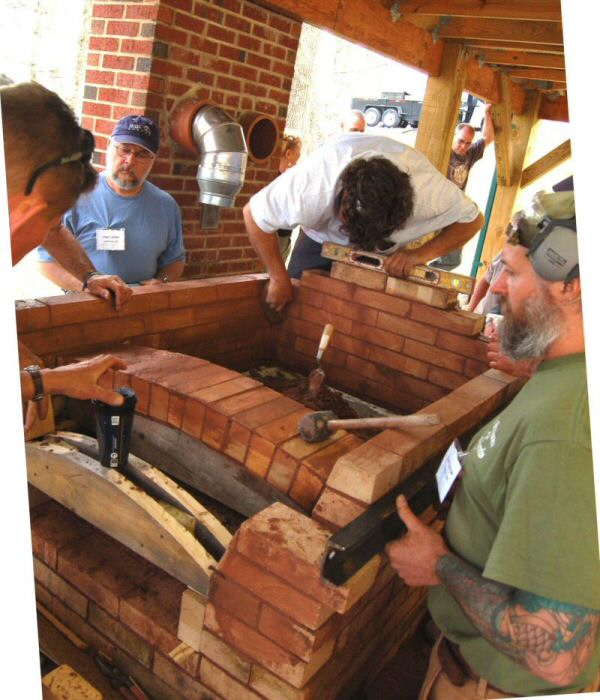

Walls;

Form for dropped arch in front, which creates a bell for the gases in the rear.

Skew course can be seen on the right.

Pegboard will cover arch forms to create a barrel vault.

The front of this dropped arch forms the rear edge of the exit throat. Bricks are rounded are chamfered at the bottom front,

and much more so in the rear.

Door arch.

Steel harness in place.

During teardown, as soon as one of the 4 bolts on the 2 threaded rods was removed, the vault collapsed.

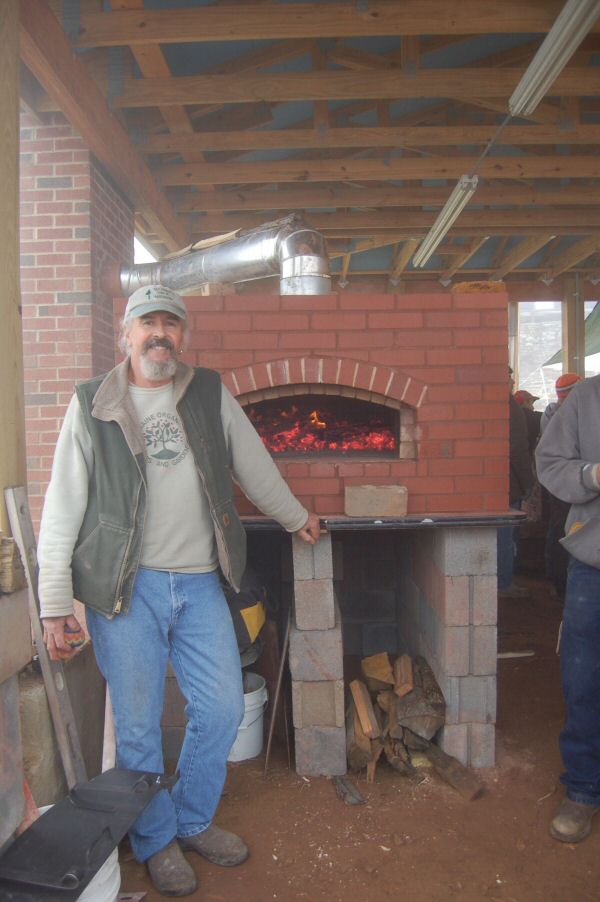

Completed vault.

Jeff Owens lays brick on the outer facing. Normally there would be a larger gap, filled with insulation.

Lighting a top down fire.

Local morel special.

The floor buckled up in the centre. Likely from the outer concrete block supports sinking into the sand

due to the weight carried by the oven walls.

Teardown.

Somebody removed a bolt from the harness to early, with sudden results.

Collapsed vault.

Heat conducted downwards through the sand underneath the hearth, and scorched the supporting

particle board table tops.

See also,

2007

Photo Report

2006 Photo Report

2004 Photo Report

2003 Photo Report

2002 Photo Report

2001 Photo Report

2000 Photo Report

1999 Photo Report

1998 Photo Report

1997 Photo Report

This page was last updated on May 1, 2011

This page was created on April 24, 2011