2018 MHA Annual Meeting

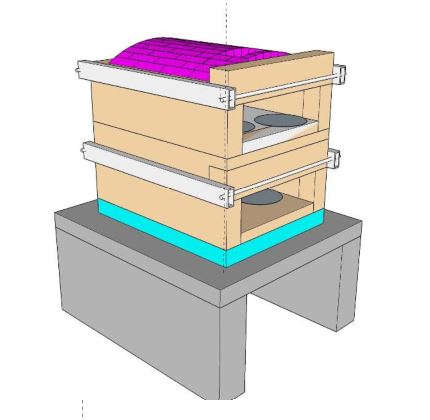

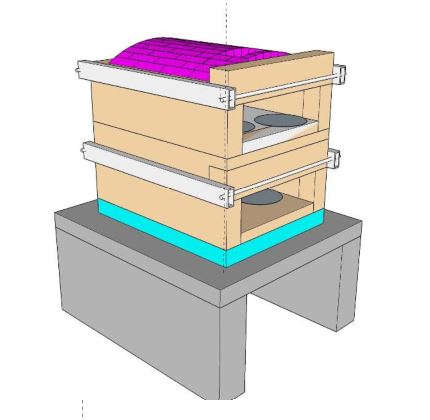

Double

Deck Oven

Photo credit: Stefan Polatschek

Download Drawings

Comments by

Jon Santiago

Photo

credit: Derek Kowalchuk

Comments

by Jon Sanitago:

The goal of this build was to get a basic feel

for double-decker ovens--how they perform and how they are

built. The design was done by Jon Santiago of Hearth +

Timber, and informed by the work of John Fisher in Europe and Jeremiah

Church/Turtlerock in the US. Potential advantages include

1)increased capacity in the same footprint, 2) increased baking per

unit of firewood used 3) diverse baking environments allowing different

foods to be cooked simultaneously 4) the ability to cook on the top

deck while firing the bottom deck allows for temperature management and

continuous cooking (almost "white" oven).

The

oven was designed for a very straightforward and fast build, with good

results on both counts. The width of the oven was laid out

specifically to match a real-time layout of 12 #1 Arch bricks so that

no ripping of tapered bricks would be necessary. The length

was likewise set so that only fulls and halfs were used along the

length. The oven was roughly close to 2' x 3' (inside hearth

dimensions). The vaults were identical in form, so that the

same form could be used twice. The lintels were cast onsite

with castable refractory. The oven core was finished in about

12 hours with a regular crew of 3-5 people (many coming and

going).

Oven drafted right away and had no trouble with

spillage except in one circumstance, with both doors wide open and a

large fire starting in the bottom deck. Once the fire and draft was

well established there was almost no spillage, and even better when the

bottom deck was closed up to a minimal air entry. The top

could be left open without spillage as long as the bottom deck opening

was reduced as it would be with a firing door. All of this done with a

chimney that went near horizontal for 6 ft before entering the masonry

chimney. oven was connected to a 7"

chimney. Height considerations prevented us from creating a

smooth, tapered transition from top deck exit to chimney connection, a

further disadvantage that makes low/no spillage more impressive.

The

oven was fired very heavily to dry it out for the pizza

party. It was fairly easy to get the bottom deck clean of

soot, but with fire only from the bottom deck, the top deck would only

clean off in about the back 1/3 of its length. readings with

an IR gun showed that with temps in the 900-1100F range on bottom

hearth/walls/vault, the top seemed to linger in a lower range, roughly

(and on average) 500-800 front to back, although temps around the

throat would approach the 900+ range.

Before

the pizza party we fired both decks at once, which thankfully caused no

problems with draft. With dual firing we were able to more or

less equalize the two decks, although the top deck hearth always lagged

behind because it is almost 10" thick in some parts.

The

pizza baking experience was a learning one! We found that

while the bottom deck was plenty hot for standard thin-crust pizza

baking, it lacked a bit of "top heat" which you get when flames like

across a dome in a standard pizza oven. Even with a large

fire in the bottom deck, the flames were immediately sucked into the

throat and away from the pizzas. This was a very subtle

problem as the pizzas were still coming out beautifully, but the top

broiling wasn't as easy as in a standard pizza oven. We then

switched to baking pizzas in the top deck with a massive fire in the

bottom deck, so that large flames were licking into the back 1/3 of the

top deck. This was great for top-broiling, but the upper deck

hearth was a little cool for 90-second pizzas. The top hearth

was so thick that it was sluggish to reach high temps and hard to

recharge.

A

couple design notes:

1)

My initial design included a "reduction lintel" on the top deck so that

gases would be forced to duck under it to exit the oven. It

was identical to the other two lintels and would create a "bell" effect

in the top deck. We decided to scratch it for simplicity and

time concerns in this workshop setting, though, and built in a central

exit right into the vault. As such gases were exiting at the

highest point of the top vault. you could feel the gas flow with your

hand and it was obviously a strong single current. As such

the front part of the top deck struggled to gain temps when only bottom

firing was used, especially the front corners. Also, the

flames had less residency along the top vault and a less disperse flow

path. I would consider including this reduction lintel in the

future, although it presents its own disadvantage in that it will

result in a cool spot of its own directly below it, and thus reduces

the usable hearth size anyway. Another option that was

considered would be to exit through two square holes built right into

the vault at the front corners of the top vault. Each of

these designs requires a more complex and larger throat complex on top

of the oven.

2)

The throat which vents the bottom deck into the top deck was built

large out of caution. It was roughly 5" by 16". It

was originally drawn around 4"x12". While firing we reduced

it in width by putting a couple splits over it, reducing the width down

to as little as 7". This resulted in a spectacular

flame-show, with the flames created tandem spirals or "rams horns" as

they follow the curve of the vault and careen downwards.

More importantly though, I think it creates more residency

time for flames in the bottom deck, and a more vigorous flaming of the

top deck. I'm not sure that starting the oven would be as

easy with a smaller throat, but depending on the chimney size and

height it may not be an issue. At any rate, I feel some sort

of adjustable damper would be a nice addition so that the throat size

could be "tuned" according the firing and cooking desires, as well as

close off the bottom deck. Max Edleson mentioned that pottery

kilns use a removable kiln shelf or thin refractory tile that can be

slid in and out of the brickwork.

3) I

would consider building the bottom vault with arch bricks cut into

"soaps", so that they have a vertical thickness of 2 1/8".

Once this vault is leveled off and the top hearth in place, it would

have a more manageable thickness with regards to heating up.

4)Another

avenue to explore would be having the gases exit each deck, or at least

the bottom deck, through a long, thin throat that is running lengthwise

along one side of the oven. This would allow the baker to

place the fire on the opposite side and thus get flames licking across

the full width of the vault during live-fire cooking, potentially

increased the "broiling" capabilities. It might also make

fire management easier for pizza baking.

Ultimately

I think a double deck oven has great potential for someone who is

willing to learn it and able to take advantage of its

versatility. It is probably not ideal for a "purist" baking

either pizza or bread, but for someone with limited space, a diverse

menu, or a culinary-pyromania complex, it could be a fantastic baking

machine.

Jon

Santiago

See

also:

2017 Photo

Report

2016 Photo

Report

2015 Photo

Report

2014 Photo

Report

2013 Photo

Report

2012 Photo

Report

2011 Photo

Report

2010 Photo

Report

2009 Photo

Report

2008 Photo

Report

2007 Photo

Report

2006 Photo Report

2004 Photo Report

2003 Photo Report

2002 Photo Report

2001 Photo Report

2000 Photo Report

1999 Photo Report

1998 Photo Report

1997 Photo Report

This

page was last updated on April 23, 2018

This page was created on April 19, 2018

Back

to: